Perfect vision is something that many people take for granted. For those who rely on eyeglasses, the ability to see the world clearly is a miracle. Among those who make quality glasses, the German optical implement manufacturer, Zeiss, is one of the best, and they make these miracles custom fit for those in need.

Zeiss makes their famous, high precision lenses in a nine-step process. The steps of the manufacturing process include: preparation, blocking, generating, polishing and engraving, deblocking and cleaning, tinting, coating, quality assurance, and glazing.

In just nine steps, this cutting-edge company creates the gift of sight to those who fail to view the world clearly. So much attention to detail goes into every set of lenses this company produces that it would be a disservice to stop at simply learning the nine steps of their process. Read on for all the details of how Zeiss makes miracles every day.

Preparation

The first step in making a set of Zeiss lenses begins when an eye care professional sends in a request from a patient. Once the order is received, the lab will ensure that the specific materials are made readily available. After this has been completed, the order will be given a barcode for easy tracking. Key parts of this step:

- Notifying all technicians and servicing equipment of the upcoming order

- Ordering necessary materials to create the lenses

- Creating a system to keep the progress of the order traceable

Two thick chunks of lens glass, called pucks, will be selected with respect to the patient’s prescription. These pucks are like a blank surface to be sculpted down into the perfect shape required for the patient’s order. Zeiss uses their original freeform technology to begin the process of customization.

Once the pucks have been prepared, they will make their way to the warehouse by way of a conveyor belt. The lenses will be transported from one step in the process to the next until a perfect set of Zeiss lenses has been specially crafted for the requesting patient. At any point in the process, the order’s progress can be viewed via the barcode.

The importance of this step stems from the function of notifying other departments of the upcoming work order. This step will allow the glasses to pass through fully prepared stations that have gathered every appropriate material for the specific order. This step sets the pace for an efficient process from the beginning until the very last station.

Blocking

In this step, the pucks are made more durable so that they can withstand the rigors of becoming Zeiss lenses. In addition to receiving a healthy coating of protective layers, the pucks will be attached to a blocker, which will allow the machines to grip and manipulate the pucks without damaging them in the process. Key aspects of this stage:

- Strengthening of the puck with the application of a protective layer

- Added surface area for machines to safely grip and maneuver

- Increase in durability to ensure that the pucks are not damaged

This step in the process is crucial. The pucks will go through several machines on their journey to become Zeiss lenses. These highly efficient machines need sufficient surface area to firmly clamp the pucks to ensure no deviation of the glass while cutting or polishing. This step could damage or ruin the lenses if done incorrectly.

Another benefit of blocking the glass is that it will allow the machines to have full access to their working area. If the clamps were to hold the glass directly, then their available surface area would be drastically limited, thus keeping the machines from properly performing their tasks. Blocking the glass improves durability and efficiency.

Blocking the glass lenses saves Zeiss a ton of money in damage and lost time. The production machines could cause serious amounts of loss in raw materials if they were not properly blocked. The added surface area allows the production machines to manipulate the working surface to ensure that the work can be done efficiently.

Generating

This step in the process of creating a set of Zeiss lenses involves the first significant shaping of the glass. From the warehouse, the glass is delivered with corrective power on the front of the lenses. The actual cutting of the lenses is done on the side that will be closest to the patient’s eyes. Key objectives of this task:

- General shaping of the lense

- Roughing of the glass

- Definition for focal points

This step uses the natural precision of a diamond to accurately shape and form the lenses to the exact prescription of the ordering customer. In this stage, the need for delicacy in the production machines can not be overstated. The lenses are becoming smaller and more fragile. It is imperative that the cutting be done with great care.

The use of the diamond for cutting is not a gimmick. Diamonds are considered the hardest material on planet Earth. This expensive material is selected to make the first cuts on Zeiss eyeglasses lenses because of its ability to hold a very sharp edge. Zeiss makes a point to utilize the finest materials and techniques in their production process.

This stage takes the pucks and shapes them down further into something that is beginning to resemble actual lenses. It is important to note that the blocking is done in the previous step adding safe durability to the glass while it is worked on with the very sharp diamond edge. There are no wasted motions in the process of creating lenses.

Polishing and Engraving

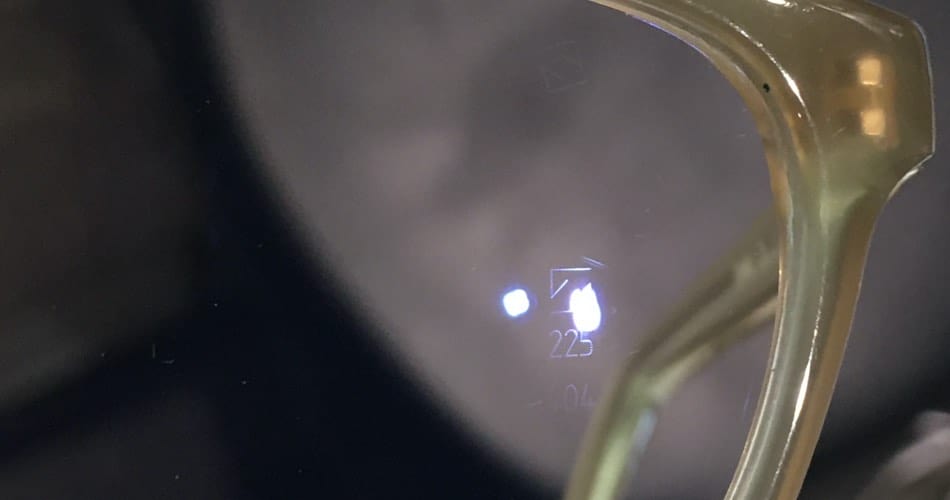

In this step, the lenses are completely smoothed, cleaned, and prepped to move down the production line. Precision is still a major priority during this step. During the engraving portion of this step, a high-powered laser will be used to mark the lenses with the nearly invisible letter Z’s. Key parts of this step:

- Complete removal of debris from lenses

- Prepping of lens glass to receive optical coatings later in the production process

- Engraving of trademark “Z” on lens glass

This stage prepares the lens glass surface to be optimal for its reception of a protective coating. This protective coating will not peel off or separate when properly adhered to the lens glass. After the lenses have been polished to absolute perfection, Zeiss proudly anoints the lens glass with its seal of authenticity with a laser engraving.

The name can sound a little unimportant, but make no mistake that this step is a critical part of the lens crafting process. Zeiss recognizes this highly important step and has invested their efforts into perfecting it. In order for the lenses to be crafted perfectly, their surface must be clean and free of debris. The polishing from the machines is a must!

Some customers may desire to have their initials engraved into the glass of their lenses. The reasons for this can range from practicality to sheer desire. No matter the reason, Zeiss is happy to offer precision engraving for the customers who invest in their products. This personal touch can set a pair apart from the rest in the production line.

Here in the picture above you can see the minimalist approach of the engraving. You will not be distracted by it while you use the lenses.

Deblocking and Cleaning

This stage involves the removal of the lenses from the blocker installed to allow the glass to be handled more carefully. The metal alloy surrounding the glass and connecting it to the blocker melts at around 50 degrees Celsius. The best way to remove this metal alloy is to submerge the lenses in hot water. Key features of this step:

- Removal of blocker and adhesive metals

- Further cleaning of lens glass to ensure optimal conditions for later production

- Environmental recycling of materials to sustain production

The lenses are then washed with brushes and cleaning agents to remove any debris. The metal alloy that is melted away from the glass and the water that does the melting are both treated and recycled for later use. Zeiss places the same amount of care in maintaining sustainable practices as it does in producing world-renowned glasses.

The worker that deblocks the glass lenses needs to be extremely careful in this step. The glass lenses have been under far more stress in the last few moments than they have ever been before. To ensure that the product can last until the next station, the worker must work with great care and deliberateness. The lenses demand caution!

As mentioned before, the surface area of the glass lenses needs to be sterile and pristine. Various debris and build-up on the glass lenses could cause them to be damaged in the next phases of the production and assembly process. Customers are expecting a flawless product, and Zeiss is out to deliver such a product to them.

Tinting

The actual tinting of the glass itself is done with layers of metal oxide. This process is very important due to the fact that each lens is crafted on the individual level to the highest quality. The purpose of the added tint will aid in the comfort of the wearer.

Key objectives of this process:

- Carefully add any tint that is requested by the customer’s order

- Ensure that the lenses are treated to their specific needs

- Ensure that the lenses are prepared for the next step of the process

Zeiss offers tinting in any and every color. It may take time for the manufacturers to create the correct color that the customer has requested for their order. Typically, tint is selected to add to the comfort of the wearer to reduce brightness when outside. Zeiss puts great care into this step of the process as they strive to achieve the perfect tint.

The tint that a customer selects can also offer the benefit of added clarity in low light situations. The reasons that a customer might elect to have a tint added to their glasses range from practicality to looks. Some customers prefer the way that certain tints and shades look on their Zeiss eyeglasses. Zeiss is happy to oblige the customer’s request.

An interesting thing to note about the tinting process on the Zeiss production line is that it is always done by a woman. All of the production workers in the tinting department of Zeiss are women. Women tend to see color more efficiently than men do. This skill is crucial when attempting to create the same shade on two different pieces of glass.

Coating

This step helps prolong the lifespan of the lenses by creating a tough outer layer that reduces the likelihood of damage. The coating will be put on in multiple layers to create a strong and durable product that can stand up to the rigors of daily use. Zeiss customers have come to expect a dependable product. Key components of this step:

- Strengthen glass and make them scratch resistant

- Improve the quality of the lenses

- Help the product to last longer

The outermost surface of the lenses will be extremely smooth, which will help repel water and dirt. This feature will keep the glass from building up debris or film that could damage the lenses at a later time. Maintenance will be much easier for the customer when they purchase Zeiss’s well coated and high-quality eyeglasses.

Another benefit of the layers of coating is the improved vision quality that certain layers can afford the wearer. Certain layers will make it easier for a wearer to see clearly in dusty conditions and rainy weather. These layers can take a disadvantaged person who struggles to see and give them a slight edge over those who have no issues at all.

A protective coating is an added layer of insurance for the ordering customer and Zeiss as well. Zeiss is proud to make glasses that work incredibly well and last beyond their intended limit of use. This special protective coating is added strength that the ordering customer can depend on for years to come. Zeiss does not skimp on the glass strength.

Added Benefits of Coating Glass

Zeiss offers customers additional coatings that they can select for their orders. These special coatings boast tons of helpful benefits to the wearer, including added protection from UV rays, easy cleaning from water and dust-repelling outer layer, and less reflection and glare on the glass itself. These are welcome benefits!

Zeiss has specially designed a coating for their glasses to protect the wearer’s eyes and the area surrounding them from the harmful UV radiation that is constantly beating down. Every single pair of clear lenses from Zeiss will come with the added bonus of UV Protect Technology. The wearer can rest assured that their vision is in good hands.

One of the most convenient features of Zeiss’s coatings is the function that makes them easier to clean. The key to this is creating a layer that reduces the build-up of static electricity, which can attract dust, dirt, and other debris. Zeiss puts great effort into creating a pristine lens for the customer to view the world through. Cleanliness is king.

The most advanced function that these coatings can offer to the wearer is nearly invisible lenses. The lenses will use a faint tint to absorb most of the glare and reflection from the lenses, which will amplify the clarity for a vivid picture everywhere that the wearer looks. Ensuring a nearly invisible lens will increase comfort dramatically.

Quality Assurance

The work is far from over when it comes to manufacturing Zeiss lenses. After the previous steps have been completed, the glasses need to be checked thoroughly to make sure that they stand up to the very high standards that Zeiss demands from its manufacturers and products alike. Key goals of this step in the process:

- Ensure that the product is up to the Zeiss standard

- Check for damage from production

- Check that each pair of glasses is clean and presentable

The glasses will need to have a thorough inspection to ensure that they meet the standards of the company. The glasses will be inspected for scratches, dirt, debris, and various damage that could have been a result of the production process. This step is the best way for Zeiss to ensure that its customers only receive the best products!

For a pair of eyeglasses to pass quality assurance, a Zeiss production worker must deem that they are, in fact, flawless. The glasses cannot have any damage or imperfections at all. Customers order Zeiss eyeglasses because they are expecting a certain level of professionalism and high-quality production. Zeiss delivers both!

Quality assurance is a crucial piece of the production puzzle and will help the company head off any bad publicity that might come from a production error and customer dissatisfaction. Zeiss wants to protect the value of their brand by ensuring that no damaged or sub-par lenses are put out to customers. Zeiss demands perfect lenses.

Glazing

Finally, the glass lenses will meet the plastic or metal frame. The pieces are all assembled, and they are now what a person would recognize as a pair of eyeglasses. From this point in the journey, they will be packaged and sent to the customer. Great care is taken at this stage to deliver the glasses safely. Key goals of this step of the process:

- Assemble the frame

- Delicately and accurately install the lenses

- Package the glasses to be sent to the ordering customer

Through every step of the process, the highest standards have been upheld to create a phenomenal product that customers have grown to depend on. It is in this stage that one can truly appreciate the satisfaction in what the good people of Zeiss are doing in the world of vision correction. Now all that is left is to try them on and see clearly!

Many times, when a person has problems with their eyeglasses, the issue rests in the union, or lack thereof, of the lenses and the frame. Zeiss heads this potential for repair off by properly addressing the union in the glazing phase. The glass lenses should stay in the frame through bumps, vibrations, and drops. The union must be life-proof.

It is the finished product that the ordering customer will see every day. It is imperative that Zeiss production workers do their absolute best to create a visually attractive and practical product for the ordering customer. The glass has been sculpted and perfected from a chunk of raw material to a miracle of technology from beginning to end.

Packaging and Sales

After the eyeglasses have been expertly produced, they will make their way to the customer. The customer can pick the glasses up from their doctor’s office or have them delivered to their home. The road from the production line to the ordering customer can be a little bumpy, so it is crucial that Zeiss employees bundle up the glasses carefully.

Some of the methods that Zeiss will depend on as they ship their product from the production line to the ordering customer are added padding, secure fastening, and sturdy packaging. Zeiss has invested the very best materials and labor into the glasses for the ordering customer. They need to ensure that the product arrives safely intact.

When Zeiss ships out a pair of eyeglasses, they will begin by filling a package with insulating and shock-absorbing foam. This foam will suspend the glasses and prevent shock from fracturing the glass or frames. This method of suspension will severely reduce the risk of the glass chipping, cracking, or becoming damaged in any way.

After the glasses have been placed into the shock-absorbing foam, they will then be fastened securely in the package to prevent any jostling on the way to their final destination. If the glasses were to rattle around freely, there is a good chance that they would be able to damage themselves. Zeiss knows how to protect its product.

Made With i.Scription Technology

Zeiss wants its customers to understand that their product is highly customizable. The biggest deciding factor for a potential customer is their prescription. After that has been established, the ordering customers can mix and match a number of different features of their eyeglasses. The best part is that they will not ever have to sacrifice on quality.

Some customers will need lenses to help them see better at night or in low light situations. It is imperative for these customers that their glasses are treated in regard to their specific vision needs. Zeiss offers i.Scription technology so that every ordering customer will rest assured that their glasses will satisfy their specific vision needs.

i.Scription technology can also make colors in regular light appear even more vivid. This can be a great benefit with a tremendous amount of practicality for the ordering customer. Increased contrast perception has also been mentioned by reviewing customers. Zeiss has changed many people’s lives with this incredible technology.

You can learn more about this technology here in this article.

Added eye-strain is a concern for many people who suffer from night blindness. Their eyes are constantly working harder to see, which can result in unnecessary eye-strain, headaches, and lack of confidence. The i.Scription technology that Zeiss has developed will greatly improve the quality of life for the ordering customer that is low-light impaired.

Zeiss Vision Quiz

Many people are unsure if they are suffering from poor contrast perception or not. Zeiss has provided these people with a test to verify whether or not they will require correction for their contrast perception. Their website has tons of information about the points in a person’s life that should coincide with regular testing of their eyes and eye function.

The rate at which testing should be conducted differs across age groups:

- Ages 20-39 should be checked three times in this time period

- Ages 40-65 should be checked at least every two years

- Ages 65 and up should be checked every year

Children should have their first examination before they turn three and a half. Their second examination should definitely happen before they are enrolled in school. Children should be checked every two years after these initial examinations to ensure that any deterioration is headed off and corrected as best as possible.

The health of the eyes should be examined regularly. Often, the changes happen over time so gradually that the patient will barely notice them. The best way to identify when correction is needed is to submit oneself to regular screening.

Conclusion

Zeiss creates the power of sight for those who struggle to see the world clearly. It is the process in which Zeiss builds miracles. It is unclear if it is more of a science or art, but one cannot deny the passion placed into every piece of glass that bears the company’s triumphant hallmark. Zeiss knows what they are doing, and it shows.

When a customer orders a pair of eyeglasses from the company Zeiss, they can rest assured that their order will be completed in a timely and highly professional manner. The customer will be making an investment in a quality piece that will improve their quality of life for years to come. That’s how Zeiss makes miracles every single day.