What needs to be said about sustainably produced frames is that the manufacturing, shipping, and sales usually rely on the use of fossil fuel-based materials. Companies that want to produce sustainably are making great strides toward the goal. Each company was able to present its concept for this article and is listed in alphabetical order.

With some companies that are to create compostable materials with other manufacturers, the focus is on planting the trees or other aid projects. Here in this article, you will learn more about sustainably produced eyewear and which of the companies presented here has worked out what kind of concept for sustainability.

Some of the companies presented here have in part produced frames sustainably while another part was processed with the common plastics, which are just not sustainable. Asking before buying helps here of course to get an overview. Since I personally have not worked with all of these companies and do not know the processes directly, I asked the following questions to the companies:

- What kind of materials do you use to produce the eyewear and how do you make sure they are sustainable?

- How is the packaging process and presentation of goods thought out to promote sustainability?

- What projects do you promote or what are additional goals that drive you?

These answers should give you, the end customer, a better overview of the sustainable eyewear on the market enjoy reading.

Mita Eyewear

- What kind of materials do you use to produce the eyewear and how do you make sure they are sustainable? We use recycled water bottles ( 5 for a pair of frame), recycled aluminum, and biodegradable lenses and nose pad. We have certificates showing the origin of the material and recycled.

- How is the packaging process and presentation of goods thought out to promote sustainability?

All our packing is made from recycled water bottles, recycled polybags and recycled paper for the outer box. - What projects do you promote or what are additional goals that drive you?

The goal is to recycle as many as water bottles as possible. We want to contribute to keep our planet a better place for future generations.

Ozeano Vision

1. What kind of materials do you use to produce the eyewear and how do you make sure they are sustainable?:

Whenever you buy products, it’s important to know what materials they’re made from, and where the materials come from. Today, many businesses cover up unsustainable and unethical practices by hiding supply chain information from their customers.

At Ozeano Vision, we have gone to great lengths to source the most sustainable and ethically produced materials from across the world for all of our products and accessories, and we ensure they are truly sustainable by only sourcing materials that have the highest standards of independent third-party certification.

The plant-based biodegradable material used for our lenses is certified by the Organic Waste Systems (OWS), the organic cotton used for our pouches and cleaning cloths is certified by Global Organic Textile Standard (GOTS), and the Portuguese Cork used for our protective cases is certified by Forest Stewardship Council (FSC). You can read more about all of the materials we use, where we source them from, and why we use them here: https://ozeanovision.com/pages/materials

2. How is the packaging process and presentation of goods thought out to promote sustainability?: Our product hang tags and certificates are made from FSC-certified natural Kraft paper and printed with waterless vegetable-based ink. Kraft paper is made from unbleached natural kraft fibers, can be entirely recycled multiple times, and is 100% biodegradable.

To ensure we’re giving back to nature, our Australian family-run supplier plants a tree for every order we place with them. All our shipping boxes are made from natural kraft board from our Melbourne-based supplier. Natural kraft is a biomaterial meaning it’s produced from all-natural ingredients such as pulp from different types of wood.

Our kraft paper is unbleached so there’s no intense chemical treatment involved, and we print on the board using UV ink – an eco-friendly alternative that doesn’t contain the carbon-based chemicals found in other inks.

All Ozeano products are shipped in home compostable courier bags with 100% biodegradable tape. Our courier bags are made from plants, corn starch to be exact, and they are certified AS 5810-2010 for Home Composting, meaning they can be put in a home compost and will break down and biodegrade within 3-6 months in a compost environment, removing the need for any toxic processes.

3. What projects do you promote or what are additional goals that drive you?

Ozeano is driven by a desire to make a difference. Our very existence centres around our ability to help protect nature’s future, with a core principle of our business being to optimise for impact, always. That means we should never settle, and always be of the mindset that we have to do more to protect people and our planet.

With that in mind, there are many social and environmental initiatives we support; with every sale 12KG (equivalent to around 1000 plastic bottles) of litter is collected from our oceans and waterways through our partnership with Sea Bin Project, and eye care treatments are funded for people in need through our partnership with Sight for All. We’re also a certified carbon-neutral company, and gold-standard member of ‘1% for the Planet.’

Pala Eyewear

- What kind of materials do you use to produce the eyewear and how do you make sure they are sustainable?

We work with Mazzucchelli M49 for our bio-actetate and their sustainable properties are covered extensively on their website. It has also been certified too which is an important part of our decision-making. We use an eco lens for our non-polarised frames made from 39.5% castor bean so increasing the amount of renewable resource over a standard lens.

- How is the packaging process and presentation of goods thought out to promote sustainability?

It’s very important as part of our overall offering. Our soft bags are made from 70% recycled PET bottles and our cases made from 100% recycled waste plastic and water sachets woven in Ghana. All our packaging is either made from recycled stock or is FSC approved.

- What projects do you promote or what are additional goals that drive you?

We are a certified B Corp which is an important part of our drive to be more sustainable and more socially responsible. It also means that legally as a business we are legally required to consider the impact of their decisions on their workers, customers, suppliers, community, and the environment.

We also unite our sales to eyecare projects in Africa through our long-standing partnership with Vision Aid Overseas. We have provided over £40,000 of grant money to various eyecare projects across Zambia, Ethiopia, and Ghana. This was the core reason for Pala beginning as a business and our growing success as a business will only mean that we can help deliver even more life-changing work.

Solo Eyewear

- What kind of materials do you use to produce the eyewear and how do you make sure they are sustainable?

We primarily use 3 materials to make our eyewear frames: repurposed wood, bamboo, and cellulose acetate. We source our wood and bamboo from furniture manufacturers. We buy their scraps which were going to be wasted and repurpose them to make our frames. We source cellulose acetate from Italian maker Mazzucchelli (https://www.mazzucchelli1849.it/). Cellulose acetate is a plant-based plastic that is biodegradable.

- How is the packaging process and presentation of goods thought out to promote sustainability?

Our packaging are made with recycled paper and our boxes are made with repurposed wood and bamboo sourced from furniture manufacturers.

- What projects do you promote or what are additional goals that drive you?

At SOLO Eyewear, we create environmentally responsible sunglasses that restore vision for people in need. We strongly believe in living a life of adventure and inspiring individuals to change the world. We donate 10% of our profit to restored vision for people in need and have helped over 15,000 people across 32 countries.

Stadtholz

- What kind of materials do you use to produce the eyewear and how do you make sure they are sustainable?

Wood, wood layers, carbon fiber parts, bio-acetate. Our Woodkinds are mostly made of waste from furniture companies, all wood parts and woods are certified and controlled (that’s the reason we do not have every woodkind in every time)

2. How is the packaging process and presentation of goods thought out to promote sustainability?

We are a family business, all is one place and we pack it by ourselves, use no plastics, recycled gluetapes and just paper etc.

3. What projects do you promote or what are additional goals that drive you?

We support different companies and ngos, for example, mantahari who stands for ocean cleaning and plastic free products to get finance for that project, we support clean the open also, we donate to different ngos like sea sheppard etc.

Waterhaul

- What kind of materials do you use to produce the eyewear and how do you make sure they are sustainable?

Our material is entirely from discarded fishing nets and ropes, which we collect from the UK coastline.

Lost or discarded fishing gear AKA ‘ghost gear’ is the most abundant form of macro-plastic in the ocean, and the problem increases by 640,000 tonnes every year. These nets are also the most lethal form of plastic to marine life. Lost in the ocean, their function to entangle marine life continues. Constructed from high-quality plastics, these nets keep on catching for over 500 years, unless removed.

Our mission is to transform this harmful ‘waste’, into a resource. The plastic nets are sorted, shredded, washed, and then melted into pellets. These pellets become our raw material, which are then injection moulded into our eyewear frames. Our frames not only directly remove plastic from our ocean and coastline, but they also have a far small carbon-footprint compared to oil-based virgin plastics.

2. How is the packaging process and presentation of goods thought out to promote sustainability?

All of our products, packaging and mailing supplies are entirely free from single-use plastic. We conducted a single-use plastic audit of our entire supply chain, ensuring that plastic use is excluded from our entire process, both behind the scenes and consumer facing. With our lens and component manufacturers, we made clear that we would not accept the standard practice of packaging these individually in plastic. Since, this has had a knock-on effect with the suppliers switching to sustainable packaging for all of their customers!

3. What projects do you promote or what are additional goals that drive you?

PlaNET Action is our one-of-a-kind educational outreach program. We deliver workshops across the UK. Utilising our portable ocean plastic recycling machines and our marine biologist educators, the programme engage and inspires the next-generation to understand the marine environment, why we should protect it, and to encourage innovative thinking.

We also recently ran a limited edition project with Ocean Conservation Namibia. We produced 100 one-of-a-kind pairs of sunglasses, made entirely from fishing line that had been removed from the necks of entangled seals during the charities dramatic rescue missions. The project raised over 5000 EUR to support their rescue work.

Zeal Optics

- What kind of materials do you use to produce the eyewear and how do you make sure they are sustainable?

We use a variety of materials in our sunglasses, with the majority being made from castor oil. Castor oil is produced from the castor plant, which is basically a weed that grows in arid soils that aren’t prime for agriculture. This replaces petroleum-based plastics in our Z-Resin frames and Ellume Polarized lenses. I’ve attached an infographic that explains the process visually.

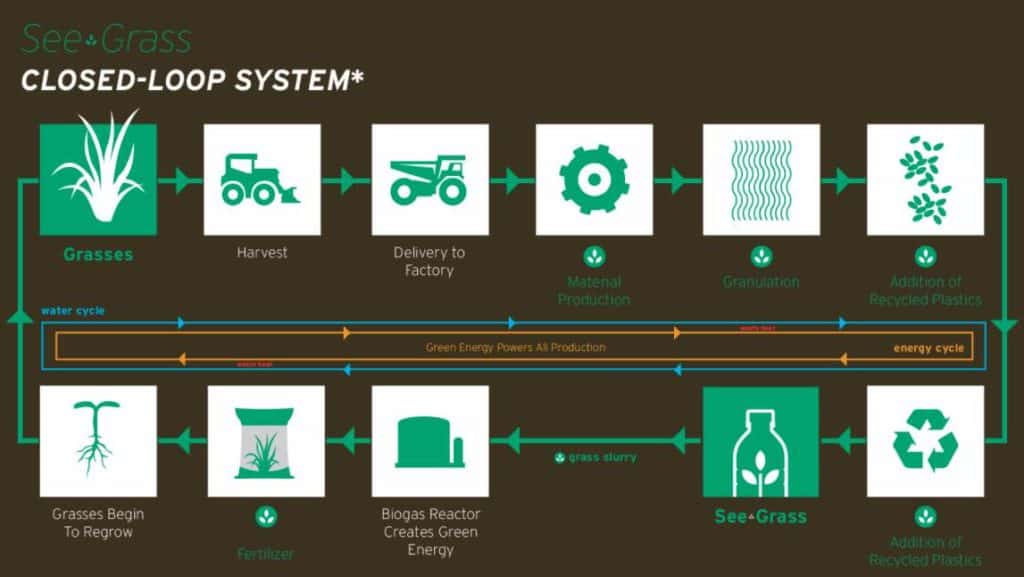

Our See Grass frames are new to the collection and we’re incredibly excited about this new material which is made from recycled PET and agricultural waste grasses in a closed-loop system.

Zeal Optics See Grass frames combine 70% recycled plastics and 30% grass fibers in a closed-loop system to create our most sustainable sunglasses yet. This fibrous base is combined with recycled plastics to reuse waste material and keep it out of landfills. See Grass allows us to create beautiful, durable sunglass frames, each of which is unique while finding alternative uses for what was previously considered trash and byproducts.

This is sourced in Germany and I’ve attached another infographic on this material.

- How is the packaging process and presentation of goods thought out to promote sustainability?

Packaging is an important focus and opportunity to further reduce our footprint. All our boxes are made from FSC-certified paper with soy-based inks and we’ve eliminated all single-use plastics from our packaging. We’re also in the process of transitioning both our hard cases and soft sunglass pouches to rPET made from recycled plastic bottles.

- What projects do you promote or what are additional goals that drive you?

At Zeal Optics, we are passionate about giving back to the places we love to explore so much. We know that when it comes to caring for the environment, it’s the little things that have the biggest impact. That’s why we have committed to contributing 1% of our gross sales to environmental causes. We’re proud to be a member of the 1% For The Planet family, and donate to non-profits that work to protect the wild places that give us so much inspiration, R&D opportunities, adventure and solace.

As you can see the approaches to sustainable eyewear are different. And depending on your preferences you can now pick your favorite brand when it comes to sustainable eyewear. The answers in these blog posts stem from the actual representatives of the manufacturers of the glasses. I emailed a lot more companies but those listed here were the ones willing to give the answers.