Unlike regular eyeglass lenses, progressive lenses actually have three separate prescriptions infused into one lens. That means you no longer need glasses specifically for reading or seeing far distances. However, progressive lenses are a lot more complicated than regular lenses and take a bit more work to create.

So, how are progressive lenses made? Here’s the general process:

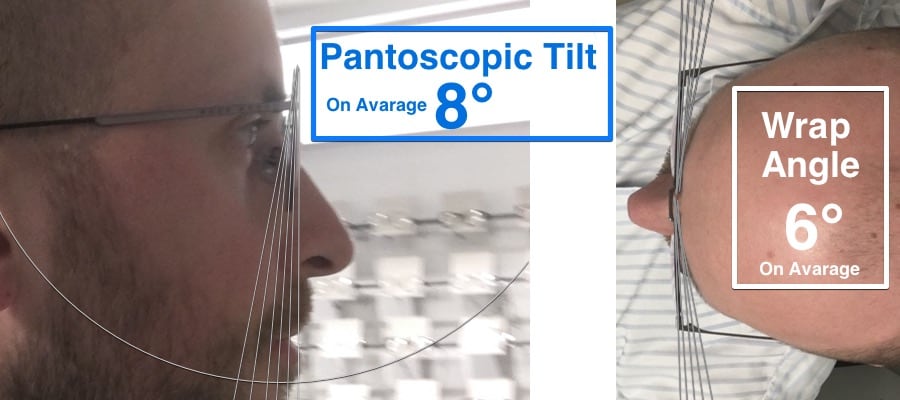

- An optometrist will measure the fitting height, your pupillary distance, pantoscopic tilt, wrap angle, the vertex distance, and more. This will help to plan out the different prescriptions in your lenses.

- The lenses are then made with the help of machines. A laser marking in this process will make sure the lenses are molded to your measurements.

Understanding exactly how eyeglass lenses are made is a little confusing. So, let’s review what progressive lenses actually are and how they’re made!

What Progressive Lenses Are

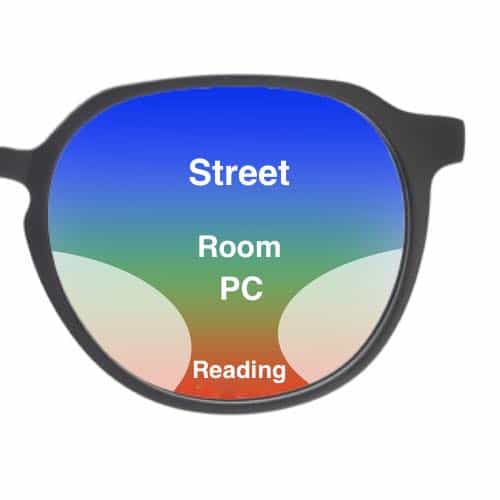

Progressive lenses are basically three different prescription glasses in one. That’s because prescription lenses are separated into three sections: Distance, intermediate, and reading. Let’s go over each of these briefly.

- Distance: The upper portion of the lens that allows you to see further by simply looking up and out into the distance

- Intermediate: The middle portion of the lens that lets you see things at a mid-range distance, such as your computer at work

- Reading: The lower portion of the lens that helps with clarity close-up when reading, just by looking down

Based on these three unique sections, the assistance that’s provided by your progressive lenses will depend on where you’re looking. What makes progressive lenses much better than regular bifocals is that the transition between the prescriptions is more gradual. So, there’s no longer a hard-line transition like you’ll see in most bifocal lenses.

Who They’re Meant For

While just about any wearer of glasses can spend extra on progressive lenses, there’s a specific community that benefits most from progressive lenses. They’re really meant for people with presbyopia, also known as far-sightedness. This condition usually affects older adults, and progressive lenses mean that only one pair of glasses is actually needed.

Keep in mind that not all frames are ideal when purchasing progressive lenses. Larger frames are usually needed in order to create this progression zone and provide the best visual experience.

Taking Measurements

When it comes to progressive lenses, getting proper measurements is more important than ever. To do so, an optician will take the time to measure where you are looking through your lenses and what you need to see relaxed and perfectly clear. This will allow you to get the perfect lenses for your vision.

Let’s go over what each of these is.

Your prescription

To get the final prescription for your progressive lenses the optometrist or optician will measure what lens power you need to see clearly in the distance and while reading. Although you did not choose a progressive lens design yet the measurement of the reading power (ADD value) will influence the progressive lens design heavily.

The more reading power you need the less clear zones you will have to perform eye movements from side to side. We have a blog post about how big the field of view probably will be in your progressive lenses. If you want to check it out just click the link.

Usually, after the optometrist knows exactly what prescription you need to talk about what distances are important to you. Then the frame gets selected and the measurements continue.

Fitting Height, Pupillary Distance and much more

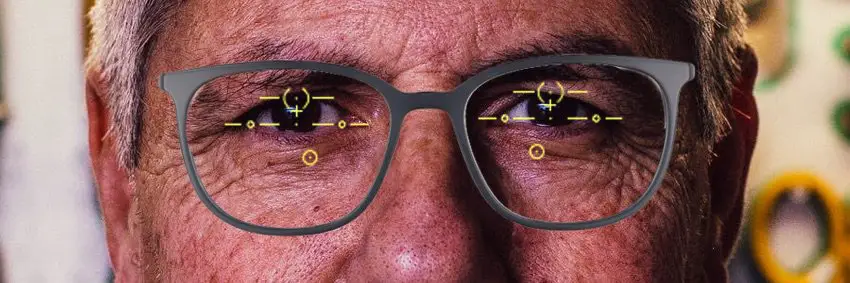

To measure the fitting height, you’ll have to wear a pair of already adjusted glasses. While you’re looking straight ahead, your optician will take a photo or video from you with a centration device. This way with special software the optician can measure exactly where you are looking through the lenses.

This way he gets measurements like:

- Pupillary Distance (the distance between your eyes)

- Fitting height (distance between pupils and the bottom of your lenses)

- Pantoscopic Tilt (how much the frame sits tilted in your face)

- Vertex distance (the distance between the lenses and your eyes)

- Wrap angle (angle between both lenses)

The fitting height describes the distance between this horizontal line and the bottom of your lenses. This is important for progressive lenses to make sure you have enough space for all three prescriptions, specifically the reading portion.

A poorly measurement might leave your vision blurry and your eyes strained. The reason is the lens design. As you have clear zones in the lens and blurry ones the optician has zero-tolerance in this centration process. When you were not looking straight ahead but performed eye movements to look into the camera your lenses will be shifted in position afterward.

But a professional optician will be aware of that and pays attention to those pitfalls. After everything got measured and the frame gets chosen the optometrist will consult you about the options in lens designs. Generally speaking, you can choose between personalized lens designs and conventional ones.

The personalized lens designs will give you higher wearing comfort and make it easier to adapt to the lenses. According to this study, 82% prefer personalized progressive lenses over conventional ones. But of course, the more personalized the lens gets for you the higher the price will be. Here you have an article from us about the costs of progressive lenses.

Now everything got talked through and measured. It is time for the optician to order your progressive lenses.

Sending It Off to the Lab

Once these measurements have been recorded, they’ll be sent out to the lab where the lens creation will begin. This is probably the most important step, given the fact that you need this exact data and measurements to create the perfect lens for your prescription.

Actually Making Progressive Lenses

The actual creation of progressive lenses is quite like the production of regular lenses. So, we’re going to walk you through how progressive lenses are actually made to fit your specific vision and prescription. We’ll start from the beginnings as plain pieces of plastic and the ending where your glasses are completed.

The Beginnings

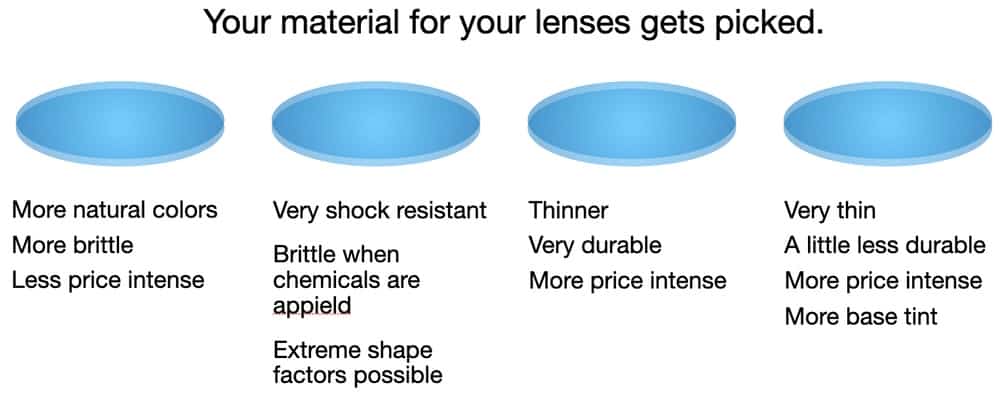

Interestingly enough, most eyeglasses start the same way. They usually come as large circles made out of plastic materials. This circle is called a “blank” and it is the ground material. There are several materials available. Each material has pros and cons of durability, thickness, and optics.

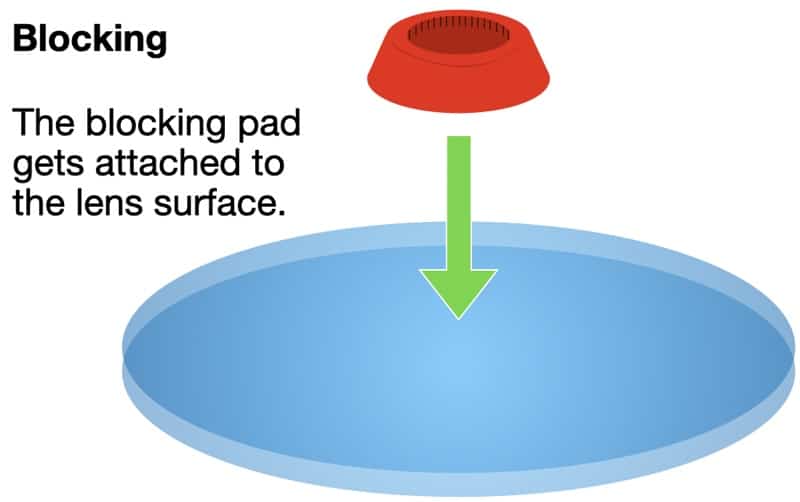

At this point, the blank needs to be made ready for the attachment of the grinding machines. This is called blocking. A very sticky pad gets attached to the lens surface to make sure the lens does not slip away while it gets spun in the CNC machine or by the applied pressure on the lens surface from the grinding tool.

Programming the Prescription

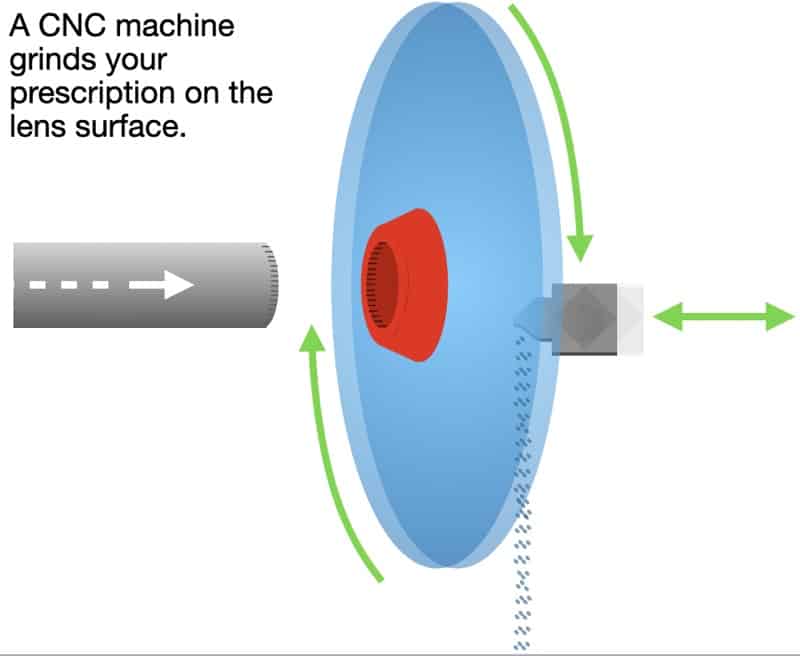

With the influx of technology, it’s no surprise that a computer system is actually what applies the prescription to your lenses. Your prescription in combination with your chosen progressive lens design is uploaded to the computer system. The system will then etch out laser engravings into the lenses to let the machine know the prescription values at each point of the lens.

Now the lens gets picked up and the grinding tool manipulates the lens surface by cutting away lens material. This is done with an accuracy of 5μm.

This is a lot more detailed than the creation of regular prescription lenses. This is where your fitting height and pupillary distance will come in handy. The machine will consider these values and mold the lens to fit these values perfectly in a little while.

Personalizing the Lenses

At this point, the machinery has taken over completely. During the cutting of the surface not only the prescribed lens power is applied to the lens surface but all individual parameters that influence the lens design. This ensures the biggest field of view and less blur.

Once the lenses have been personalized, they’re then polished to create a smoother texture and clear vision. The sticky pad installed before is now removed, to expose the rest of the lens.

Tints

There is always a variety of possible tints you could choose from in all kinds of intensities. If you have a favorite color most labs will even consider this and dye the lenses after your optician send them your sample. This process usually is still made by hand to this day.

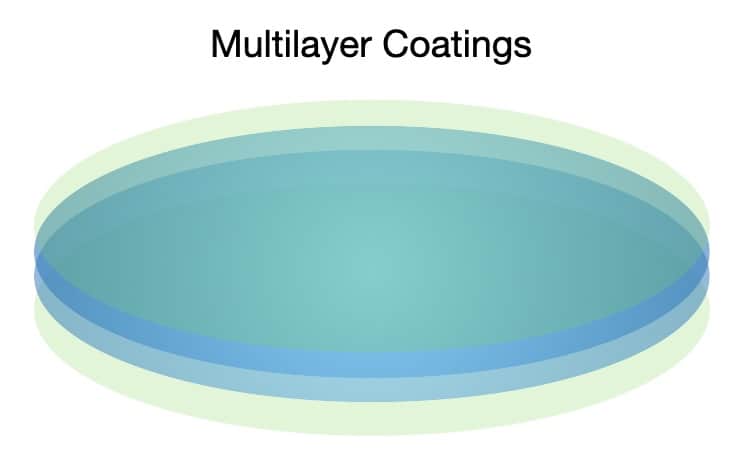

Coatings

There is a multilayer of coatings applied to the lens surface to provide you with less disturbing reflections, more durability, and surface that is easier to clean. Depending on the chosen coating it is applied to the lens by spin coating or by evaporating.

durable, more transparent and easier to clean.

Nearly every supplier of progressive lenses provide different coatings. Some of them are harder and more resistant to scratches, some are easier to clean or are less price intense.

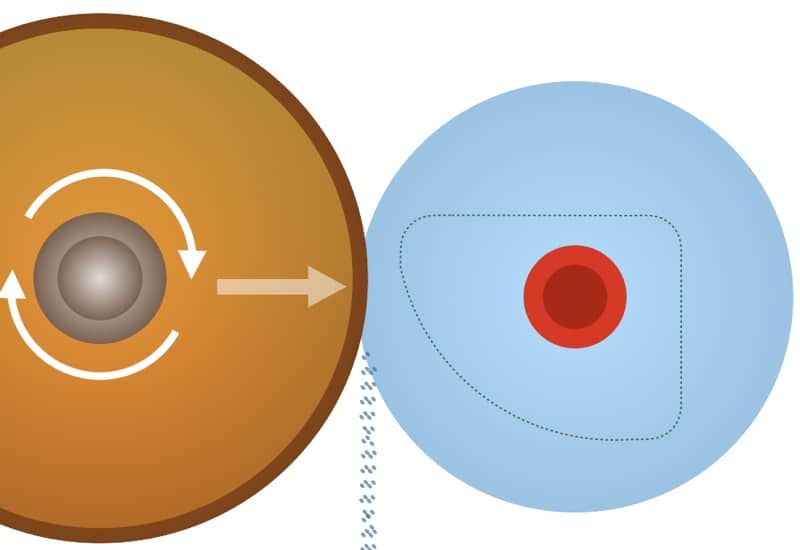

Lens Edging and Insertion or Mounting

Another computer system will then measure your chosen frames and another CNC machine slices out your lenses to this exact shape. The lenses are then installed into your brand new frames, and your glasses are checked for quality by professionals.

Conclusion

Though progressive lenses are much more advanced than regular eyeglass lenses, they’re made in quite a similar fashion. But although you can not see much of a difference compared to regular lenses the shape of the lens surface is far more complex. That´s why every little count when it comes to the precision of the opticians and optometrists measurements.

Failure to do so will cause eye strain and a headache.

If you want more to know about how progressive lenses are made just visit your optician. I bet he or she will be delighted to show his edgers, blockers, and more to show this process live to you.

During all the steps here a jumped over some details to not blow the article up to much.

I wish you a great day.